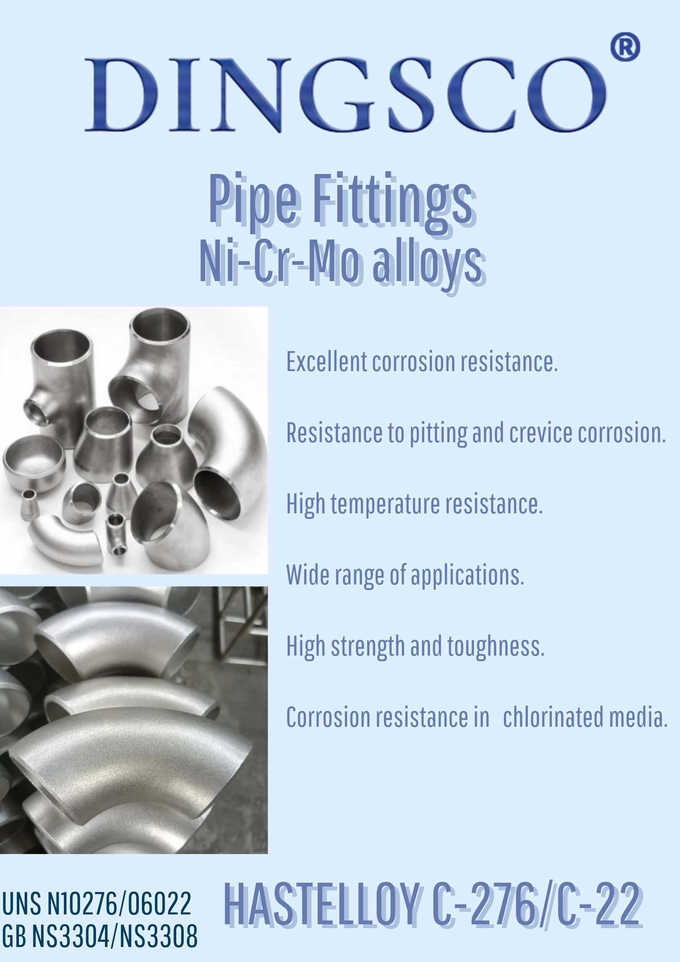

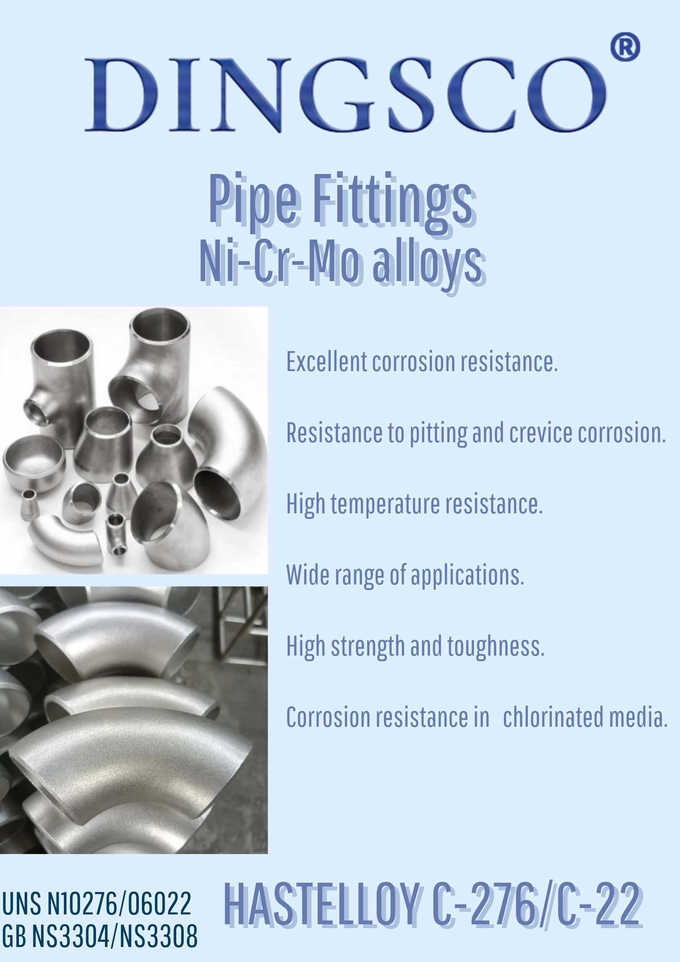

UNS N10276 N06022 Nickel Alloy Pipe Fittings Hastelloy Customized

Tube Fittings

In order to ensure its performance and extend its service life, the

maintenance and cleaning operations of nickel alloy pipe fittings

need to pay attention to the following aspects:

Clean:

1. Use mild cleaners: Avoid using cleaners containing chlorine, phosphoric acid, or

sulfuric acid, as these chemicals can damage the surface of nickel

alloys.

2. Use a soft cloth or non-abrasive sponge: Avoid using abrasive cleaning tools such as steel wool, which may

scratch the surface of the fitting.

3. Frequency of cleaning: Depending on the usage environment, clean regularly to remove

dirt and corrosion that may have accumulated.

Examine:

1. Regular Inspections: Regularly inspect pipe fittings for any visible damage, such as

scratches, cracks, or corrosion.

2. Check connections: Make sure all connections are tight to prevent leaks.

Anti-corrosion measures:

1. Coating protection: Apply anti-corrosion coating or anodic protection to the surface

of pipe fittings to enhance its corrosion resistance.

2. Avoid Exposure to Moisture: Minimize exposure of pipe fittings to high humidity or moisture,

as this may accelerate the corrosion process.

Installation and maintenance:

1. Proper installation: Make sure pipe fittings are installed correctly according to the

manufacturer's instructions to avoid damage caused by improper

installation.

2. Use the right tools: Use the right tools during installation or maintenance and avoid

using excessive force to avoid damaging the fittings.

Storage:

1. Dry storage: When storing nickel alloy pipe fittings, ensure that the storage

environment is dry and avoid direct exposure to sunlight or humid

places.

2. Avoid stacking: Do not stack heavy objects on fittings to prevent deformation or

damage.

Professional maintenance:

1. Regular professional inspections: For critical or high-demand systems, regular inspection and

maintenance by professionals is recommended.

Following these maintenance and cleaning precautions can help

ensure that nickel alloy pipe fittings maintain optimal performance

and corrosion resistance throughout their expected service life.

| Grade | Chemical Composition(%) | Tensile Strength

(Mpa min) | Yield Strength

(Mpa min) | Reduction of Area, min (%) | Elongation

min(%) | Hardness

(HRC) |

|

HASTELLOY C-276 | Ni | Co | Cr | Mo | W | P | Fe | 690 MPa min | 283 MPa min | …. | 40% min | HRC 35 max |

| Remainder | 2.5max | 14.5-16.5 | 15.0-17.0 | 3.0-4.5 | 0.04max | 4.0-7.0 |

| Si | Mn | C | V | S | | |

| 0.08max | 1.0max | 0.01max | 0.35max | 0.03max | | |

| HASTELLOY C-22 | Ni | Mo | Cr | Fe | Co | P | W | 690 MPa min | 310 MPa min | …. | 60% min | HRC 41 max |

| Remainder | 12.5-14.5 | 20.0-22.5 | 2.0-6.0 | 2.5max | 0.02max | 2.5-3.5 |

| V | C | Mn | Si | S | | |

| 0.35max | 0.015max | 0.5max | 0.08max | 0.02max | | |

| GRADE | UNS | DENSITY | MELTING RANGE | DIN | GB |

| HASTELLOY C-276 | UNS N10276 | 8.87g/cm³ | 1325-1370°C | W.NR.2.4819 | NS3304 |

| HASTELLOY C-22 | UNS N06022 | 8.69g/cm³ | 1325-1370°C | W.NR.2.4602 | NS3308 |