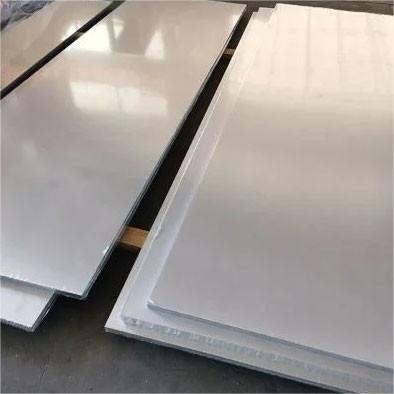

Super Nickel Based Alloy Sheet Corrosion Resistance Incoloy 825 UNS

N08825 Nickel Alloy Plate

INCOLOY 825:

Incoloy 825 is a high-performance nickel-iron-chromium alloy. Its

chemical composition includes nickel (38-46%), chromium

(19.5-23.5%), iron (balance), carbon (≤0.025%), manganese (≤1.0 %),

silicon (≤0.5%), copper (1.5-3.0%), molybdenum (2.5-3.5%), aluminum

(≤0.2%), titanium (0.6-1.2%) and other elements. The physical

properties of this alloy include a density of 8.14 g/cm³ and a

melting point of 1370-1400°C. At normal temperature, its minimum

mechanical properties include tensile strength 550 N/mm², yield

strength 220 N/mm², elongation 30% and Brinell hardness ≤ 200.

The properties of Incoloy 825 include good resistance to stress

corrosion cracking, pitting and crevice corrosion, resistance to

oxidizing and non-oxidizing hot acids, and good mechanical

properties at room temperature and at elevated temperatures up to

550°C. In addition, the alloy has certification for manufacturing

pressure vessels up to 450°C.

Incoloy 825 is widely used in various industrial fields where the

operating temperature does not exceed 550°C, such as heating tubes,

containers, baskets and chains used in sulfuric acid pickling

plants, seawater cooling heat exchangers, marine product pipeline

systems, acid gas environment pipelines, Heat exchangers,

evaporators, washers, dip tubes, etc. in phosphoric acid

production, air heat exchangers in petroleum refining, food

engineering, chemical processes, and flame retardant alloys for

pressurized oxygen applications.

Incoloy 825 is suitable for welding with the same material or other

metals using any traditional welding process, such as tungsten

electrode inert gas shielded welding, plasma arc welding, manual

sub-arc welding, metal electrode inert gas shielded welding, and

melting electrode inert gas shielded welding. When using manual arc

welding, it is recommended to use a shielding gas mixed with

(Ar+He+H2+CO2) multiple components. Welding must be carried out in

the annealed state, and stains, dust and various marks must be

cleaned with a stainless steel wire brush.

| GRADE | UNS | DENSITY | DIN | GB |

| INCOLOY 825 | UNS N08825 | 8.14g/cm³ | W.NR.2.4858 | NS1402 |

CHEMICAL COMPOSITION:

| Ni | C | Fe | Mn | Cr | S | Mo |

| 38.0 - 46.0 | 0.05max | 22.0min | 1.0max | 19.5 - 23.5 | 0.03max | 2.5 - 3.5 |

| Si | Cu | Al | Ti | | | |

| 0.5max | 1.5 - 3.0 | 0.2max | 0.6 - 1.2 | | | |

SPECIFICATION:

| FORM | ASTM |

| Rod and bar | B 425 |

| Plate, sheet and strip | B 424, B 906 |

| Seamless pipe and tube | B 423, B 829 |

| Welded pipe | B 705, B 775 |

| Welded tube | B 704, B 751 |

| Fitting | B 366 |

| Forging | B 564 |

| |

| |