| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickel Alloy Forging Bar : It takes a billet and heats it until it is malleable, forging either hammers or presses the bar to the rough dimensions required. The operation gives the bar a 3:1 reduction ratio minimum, which means that the grain sizes are much smaller and tighter in a forged bar, and it consolidates the centers if there are any piping issues. Then, depending on the diameter of the bar, the bar is put through a planishing mill giving it a smooth, rounded surface.

Manufacturing Process: Forging bars are created through a forging process that involves heating metal billets to high temperatures and applying pressure to shape them into the desired form. The metal is subjected to compressive forces, which refine the grain structure and enhance the mechanical properties. The forging process results in superior strength, toughness, and resistance to fatigue. It ensures a consistent and homogeneous structure throughout the bar, minimizing the risk of internal defects.

Mechanical Properties: Forging bars possess exceptional mechanical properties due to the forging process. The compressive forces applied during forging result in a refined grain structure, leading to improved strength, toughness, and resistance to impact and fatigue. Forging Bar have a high load-bearing capacity and can withstand severe conditions without failure. They are commonly used in critical applications that demand superior mechanical performance and reliability.

Applications:

Forged bars are extensively used in industries that require high strength, durability, and resistance to fatigue. Some common applications include:

Monel 400 (UNS NO4400/W.Nr. 2.4360) is a nickel-copper alloy (about 67% Ni- 23% Cu) that is resistant to sea water and steam at high temperatures aswel as to salt and caustic solutions. Aloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloyexhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowingbrackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to avariety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions.

Pickling

Pickling can produce bright, clean surfaces on Alloy 400.

Fabricating

Alloy 400 is readily fabricated by standard processes.

Hot Forming

One procedure for producing forgings to such specifications consists of taking 30-35% reduction following the final reheat.

This is accomplished as follows:

High-tensile forgings, as described in certain military specifications, also require a minimum of 30-35% reduction following the last reheat. This is taken in the following manner:

Cold Forming

Alloy 400 is adaptable to virtually all methods of cold fabrication. The forces required and the rate of work hardening are intermediate between those of mild steel and Type 304 stainless steel.

Chemical Composition:

| Element | C | Si | Mn | S | Cu | Fe | Ni+Co | Co |

| Minimum(%) | - | - | - | - | 28 | - | 63 | - |

| Max(%) | 0.3 | 0.5 | 2 | 0.024 | 34 | 2.5 | 70 | 2 |

Nature:

| State | Approximate tensile strength (N/mm²) | Approximate Operating Temperature(°C) |

| Annealing | 400-600 | -200 to +230 |

| Elastic tempering | 800-1100 | -200 to +230 |

Tensile Properties of MONEL Alloy 400 at Low Temperatures:

| Temper | Temperature, °F | Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Elongation, % | Reduction of Area, % |

| Cold-Drawn | Room | 103.80 | 93.70 | 19.0 | 71.0 |

| -110 | 117.45 | 100.85 | 21.8 | 70.2 | |

| Rooma | 103.40 | 93.30 | 17.3 | 72.5 | |

| Forged | 70 | 92.00 | 67.00 | 31.0 | 72.7 |

| -297 | 128.25 | 91.50 | 44.5 | 71.8 | |

| -423 | 142.00 | 96.40 | 38.5 | 61.0 | |

| Annealed | 70 | 78.65 | 31.30 | 51.5 | 75.0 |

| -297 | 115.25 | 49.50 | 49.5 | 73.9 | |

| aHeld at -110°F for several hours prior to testing at room temperature. | |||||

Our QC Activities and Test Methods:

| Chemical Analysis | ASTM E1473ensile | Test | ASTM E8 |

| Hardness Test | ASTM E 10,E 18 | PMl Examination | DINGSCO SOP |

| Ultrasonic NDT | BS EN 10228 | Liquid Penetrant NDT | ASTM E 165 |

| Dimensional and inspection | DINGSCO SOP | Roughness Test | DINGSCO SOP |

| Impact Test | ASTM E 23 | Low Temperature lmpact Test | ASTM E 23 |

| Creep and Stress Rupture Test | ASTM E 139 | Hydrogen Induced Cracking Test | NACE TM-0284 * |

| Inter Granular Corrosion Test | ASTM A 262 * | Sulfide Stress Corrosion Cracking Test | NACE TM-0177 * |

| Pitting and Crevice Corrosion Test | ASTM G 48 * | Macro Etching Test | ASTM E 340* |

| Grain Size Test | ASTM E 112 * |

* Done by state own third party laboratory

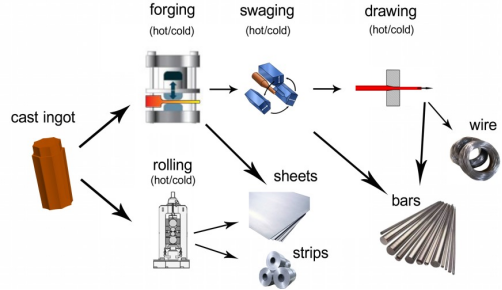

Processing Flow Chart:

|