| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickle Alloy Forging Discs Monel K500 UNS N05500 Centrifugal Pumps Marine Industry

Nickle Alloy disc, a thin, projecting metal stripattached to asemiconductor to dissipateheat. It is widely used incatering and kitchenware, elevators, chemical equipment, machinery manufacturing, architectural decoration, metaproducts, automobiles, pressurevessels and other felds.

Monel K500, is a age-hardenablenickel-copper alloy that combines the corrosion resistanceproperties of Monel 400 with high strength corrosion fatigue and erosion resistance properties. It is precipitation hardenable through theadditions of aluminum and titanium. The chemica composition of It retains the excellent corrosionresistant characteristics of alloy 400.When compared with Monel 400, it has enhanced strength and hardnessafter precipitation hardening. It has approximately three times the yield strength and doublethe tensile strength of alloy 400.It can befurther strengthened oy cold working before the orecipitation hardening. It should be annealed when welded and theweldment then stress relieved before aging.

Machining:

Nickel based alloys can be difficult tomachinine.However, it should

be emphasized that thesealloys can be machined using conventional

productionmethods at satisfactory rates. These alloys harden

rapidlygenerate high heat during cutting, weld to the cuttingtool

surface and offer high resistance to metal removabecause of their

high shear strengths. The following arekey points which should be

considered during machining operations: capacity/tools/positive

cut/lubrication.

Recommended Tool Types & Machining Conditions:

| Operations | Carbide Tools |

| Roughing, with severeinterruption | Turning or Facing C-2 andC-3 grade: Negative rakesquare insert, 45° SCEA1,1/32 in. nose radius. Tooholder: 5° neg. back rake5° neg. side rake. Speed:30-50 sfm,0.004-0.008 in.feed, 0.150 in depth of cut.Dry2, oil3, or water-base coolant 4. |

| Normal roughing | Turning or Facing C-2 orC-3 grade: Negative ratesquare insert, 45° SCEA,1/32 in nose radius. Tooholder: 5° neg. back rake5° neg. side rake. Speed:90 sfm depending on rigidity of set up, 0.010 infeed, 0.150 in. depth ofcut. Dry, oil, or water-base coolant. |

| Finishing | Turning or Facing C-2 0rC-3 grade: Positive rakesquare insert, if possible45° SCEA, 1/32 in.noseradius. Tool holder: 5° pos.back rake, 5° pos. siderake.Speed: 95-110 sfm0.005-0.007 in. feed,0.040 in. depth of cut. Dryor water-base coolant. |

| Rough Boring | C-2 or C-3 grade: lf inserttype boring bar, use standard positive raketools with largest possibleSCEA and 1/16 in. nose radius. lf brazed tool bargrind 0° back rake, 10° posside rake, 1/32 in. nose radius and largest possible SCEA.Speed: 70 sfm depending on the rigidityof setup, 0.005-0.008 infeed, 1/8 in. depth of cut.Dry, oil or water-base coolant. |

| Finish Boring | C-2 or C-3 grade: Usestandard positive raketools on insert type bars.Grind brazed tools as fofinish turning and facingexcept back rake may bebest at 0°. Speed: 95-110sfm,0.002-0.004 in feed.Water-base coolant. |

Chemical Composition:

| Element | Ni | Cu | C | Mn | Fe | S | Si | Al | Ti |

| Minimum(%) | 63 | 27 | - | - | - | - | - | 2.3 | 0.35 |

| Max(%) | - | 33 | 0.25 | 1.5 | 2.0 | 0.01 | 0.5 | 3.15 | 0.85 |

Thermal Properties:

| Temperature | Mean Linear Expansiona | Thermal Conductivityb | Specific Heatb | Electrical Resistivityc | |||||

| °F | °C | in/in/°F x 10-6 | µm/m•°C | Btu-in/h/ft2 /°F | W/m•°C | Btu/lb/°F | J/kg•°C | ohm-circ mil/ft | µΩ•m |

| -320 | -200 | 6.2 | 11.2 | - | - | - | - | 330.8d | 0.550 |

| -250 | -157 | 6.5 | 11.7 | 86 | 12.3 | 0.071 | 297.3 | - | - |

| -200 | -130 | 6.8 | 12.2 | 92 | 13.1 | 0.077 | 322.4 | - | - |

| -100 | -70 | 7.2 | 13.0 | 103 | 14.7 | 0.087 | 364.3 | - | - |

| 70 | 21 | - | - | 121 | 17.2 | 0.100 | 418.7 | 370 | 0.615 |

| 200 | 100 | 7.6 | 13.7 | 136 | 19.4 | 0.107 | 448.0 | 372 | 0.618 |

| 400 | 200 | 8.1 | 14.8 | 156 | 22.2 | 0.114 | 477.3 | 378 | 0.628 |

| 600 | 300 | 8.3 | 14.9 | 178 | 25.4 | 0.117 | 489.9 | 385 | 0.640 |

| 800 | 400 | 8.5 | 15.3 | 198 | 28.2 | 0.120 | 502.4 | 390 | 0.648 |

| 1000 | 500 | 8.7 | 15.7 | 220 | 31.4 | 0.125 | 523.4 | 393 | 0.653 |

| 1200 | 600 | 9.1 | 16.4 | 240 | 34.2 | 0.132 | 552.7 | 396 | 0.658 |

| 1400 | 700 | 9.3 | 16.7 | 262 | 37.3 | 0.141 | 590.3 | 400 | 0.665 |

| 1600 | 800 | 9.6 | 17.3 | 282 | 40.2 | 0.157 | 657.3 | 408 | 0.678 |

| 1800 | 900 | - | - | 302e | 43.1 | 0.186e | 778.7 | 418 | 0.695 |

aBetween 70°F (21°C) and temperature shown. Age-hardened material. bMaterial was in the annealed condition prior to test. cElectrical resistivity is markedly influenced by thermal history because of the age- hardening characteristics of the alloy. The data shown represent values measured on decreasing temperature on material in an equivalent to annealed condition with a small amount of age hardening. dResistivity of sample from this test tested at room temperature: 355.5 ohm/circ mil/ft. eExtrapolated. | |||||||||

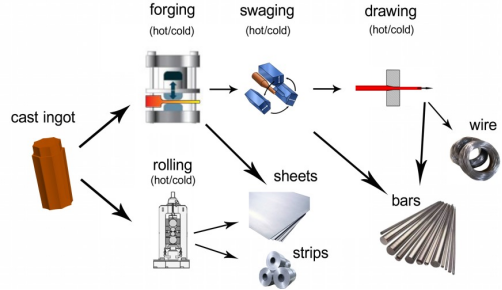

Processing Flow Chart:

|