| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Welding wires are slim metallic wires that are usually coiled up in spools. These spools are loaded on a wire feeder and the welding wire is continuously fed through a welding gun into the molten weld pool. As a result, arc welding processes that use a welding wire tend to offer higher deposition rates and faster travel speeds, as compared to TIG and Stick welding where the welder must manually feed the filler metal into the weld puddle.

Monel 400 (UNS NO4400/W.Nr. 2.4360) is a nickel-copper alloy (about 67% Ni- 23% Cu) that is resistant to sea water and steam at high temperatures aswel as to salt and caustic solutions. Aloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloyexhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowingbrackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to avariety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions.

Corrosion Data:

Monel alloy 400 offers great stress corrosion cracking in most freshwaters. Due to Copper it offers resistance to marine application ( salt water ), steam water even at high temperature. Good Resistance to hydrochloric acid , sulphuric acids while de-aerated. Resistance to Neutral & Alkaline salts. Resistance to chloride stress corrosion cracking.

Chemical Composition:

| Element | C | Si | Mn | S | Cu | Fe | Ni+Co | Co |

| Minimum(%) | - | - | - | - | 28 | - | 63 | - |

| Max(%) | 0.3 | 0.5 | 2 | 0.024 | 34 | 2.5 | 70 | 2 |

Nature:

| State | Approximate tensile strength (N/mm²) | Approximate Operating Temperature(°C) |

| Annealing | 400-600 | -200 to +230 |

| Elastic tempering | 800-1100 | -200 to +230 |

Tensile Properties of MONEL Alloy 400 at Low Temperatures:

| Temper | Temperature, °F | Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Elongation, % | Reduction of Area, % |

| Cold-Drawn | Room | 103.80 | 93.70 | 19.0 | 71.0 |

| -110 | 117.45 | 100.85 | 21.8 | 70.2 | |

| Rooma | 103.40 | 93.30 | 17.3 | 72.5 | |

| Forged | 70 | 92.00 | 67.00 | 31.0 | 72.7 |

| -297 | 128.25 | 91.50 | 44.5 | 71.8 | |

| -423 | 142.00 | 96.40 | 38.5 | 61.0 | |

| Annealed | 70 | 78.65 | 31.30 | 51.5 | 75.0 |

| -297 | 115.25 | 49.50 | 49.5 | 73.9 | |

| aHeld at -110°F for several hours prior to testing at room temperature. | |||||

Our QC Activities and Test Methods:

| Chemical Analysis | ASTM E1473ensile | Test | ASTM E8 |

| Hardness Test | ASTM E 10,E 18 | PMl Examination | DINGSCO SOP |

| Ultrasonic NDT | BS EN 10228 | Liquid Penetrant NDT | ASTM E 165 |

| Dimensional and inspection | DINGSCO SOP | Roughness Test | DINGSCO SOP |

| Impact Test | ASTM E 23 | Low Temperature lmpact Test | ASTM E 23 |

| Creep and Stress Rupture Test | ASTM E 139 | Hydrogen Induced Cracking Test | NACE TM-0284 * |

| Inter Granular Corrosion Test | ASTM A 262 * | Sulfide Stress Corrosion Cracking Test | NACE TM-0177 * |

| Pitting and Crevice Corrosion Test | ASTM G 48 * | Macro Etching Test | ASTM E 340* |

| Grain Size Test | ASTM E 112 * |

* Done by state own third party laboratory

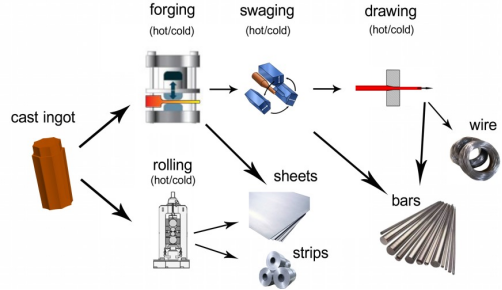

Processing Flow Chart:

|