| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Welding wires are slim metallic wires that are usually coiled up in spools. These spools are loaded on a wire feeder and the welding wire is continuously fed through a welding gun into the molten weld pool. As a result, arc welding processes that use a welding wire tend to offer higher deposition rates and faster travel speeds, as compared to TIG and Stick welding where the welder must manually feed the filler metal into the weld puddle.

Inconel 718(UNS NO7718) is a GammaPrime strengthened aloy with excelent mechanicalproperties at elevated temperatures, as wel as cryogenidtemperatures. Suitable for temperatures up to around1300 °F. Can be readily worked and age hardened. Excellent strength from -423 °Fto 1300°F(-253 'C to 705C).Age hardenable and may be welded in fully agedcondition, Excellent oxidation resistance up to 1800 °F(980 °C).Typically sold in the solution annealed temperbut can be ordered aged, cold worked, or cold worked &aged. Alloy 718 is a high strength, nickel base, superalloy usedfor cryogenic temperatures up to long term service at1200 °F. This alloy is readily fabricated and may be weldedin either the annealed or precipitation hardened(aged)condition.718 is annealed at 1700-1850 'F and air cooledor faster. lt is aged at 1325 °F for 8 hours, furnace cooledto hold at 1150 'F, for a total aging time of 18 hours, thenair cooled.Alloy 718 wil show a contraction of 0.0008inch/inch after precipitation hardening. Good mechanical properties: tensile,fatigue, and creep-rupture. Excelent welding characteristics and resistant to postweld age cracking. Oxidation resistant throughout its useful temperature range.

Applications:

Uses for this alloy tend to be in the field of gas

turbinecomponents and cryogenic storage tanks. Alloy 718 iscommonly

used in jet engines, pump bodies and partsrocket motors and thrust

reversers, and hot extrusiontooling.Other popular uses are high

strength bolting anddown hole shafting.

Chemical Composition:

| ment | Ni | Cr | S | C | Mn | Si | Mo | Cu | Co | Al | Nb | B | P |

| Minimum(%) | 50 | 17 | - | - | - | - | 2.8 | - | - | 0.2 | 4.75 | - | - |

| Max(%) | 55 | 21 | 0.015 | 0.08 | 0.35 | 0.35 | 3.3 | 0.3 | 1.0 | 0.8 | 5.5 | 0.006 | 0.015 |

Mechanical Properties:

| Properties | YS(Ksi) | TS(Ksi) | EL(%) | HRC |

| Room Temperature | 180 | 150 | 12 | 36 |

| 1200℉(<0.025-in) | 140 | 115 | - | - |

| 1200℉(>0.025-in ) | 145 | 120 | 5 | - |

Thermal Properties:

| Temperature, °F | Thermal Conductivitya, BTU•in/ft2 •h•°F | Electrical Resistivitya, ohm circ mil/ft | Mean Linear Expansionb,c, in/in/°F x 10-6 | ||

| Ann. 1800°F/1 hr | Ann. + Aged | Ann. 1800°F/1 hr | Ann + Aged | ||

| -320 | - | - | - | - | 5.9d |

| 70 | 77 | 79 | 753 | 725 | - |

| 200 | 86 | 87 | 762 | 733 | 7.31 |

| 400 | 98 | 100 | 772 | 755 | 7.53 |

| 600 | 111 | 112 | 775 | 768 | 7.74 |

| 800 | 123 | 124 | 784 | 775 | 7.97 |

| 1000 | 135 | 136 | 798 | 788 | 8.09 |

| 1200 | 147 | 148 | 805 | 794 | 8.39 |

| 1400 | 160 | 161 | 802 | 797 | 8.91 |

| 1600 | 173 | 173 | 799 | 796 | - |

| 1800 | 185 | 186 | 801 | 800 | - |

| 2000 | 196 | 199 | 811 | 796 | - |

aAnnealing was 1800°F/1 hr; aging was 1325°F/8 hr, F.C. 20°/hr to 1150°F, held at 1150°F for total aging time of 18 hr. Conductivity calculated from resistivity values. bFrom 70°F to temperature shown. cAnnealed 1750°F/1 hr and aged 1325°F/8 hr, F.C. to 1150°F/8 hr, A.C. d Samples tested were in both the annealed (1750°F/1 hr, A.C.) and annealed and aged (1750°F/1 hr + 1325°F/8 hr, F.C. to 1150°F, held at 1150°F for 10 hr, A.C.) conditions. | |||||

Our QC Activities and Test Methods:

| Chemical Analysis | ASTM E1473ensile | Test | ASTM E8 |

| Hardness Test | ASTM E 10,E 18 | PMl Examination | DINGSCO SOP |

| Ultrasonic NDT | BS EN 10228 | Liquid Penetrant NDT | ASTM E 165 |

| Dimensional and inspection | DINGSCO SOP | Roughness Test | DINGSCO SOP |

| Impact Test | ASTM E 23 | Low Temperature lmpact Test | ASTM E 23 |

| Creep and Stress Rupture Test | ASTM E 139 | Hydrogen Induced Cracking Test | NACE TM-0284 * |

| Inter Granular Corrosion Test | ASTM A 262 * | Sulfide Stress Corrosion Cracking Test | NACE TM-0177 * |

| Pitting and Crevice Corrosion Test | ASTM G 48 * | Macro Etching Test | ASTM E 340* |

| Grain Size Test | ASTM E 112 * |

* Done by state own third party laboratory

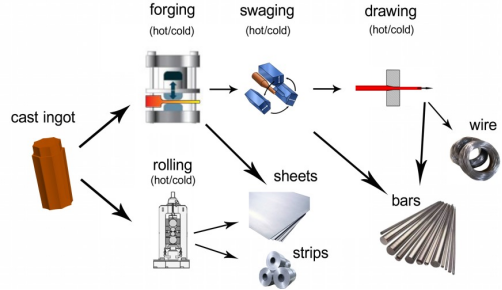

Processing Flow Chart:

|