| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickel Alloy Forging Ring Inconel 600 UNS N06600 Roller Hearths Radiant Tubes

Nickle Alloy Ring are the most common in forged metals. Through open die forging,the metal is formed into something that's shaped like a doughnubefore it's heated between 400 and 700'c. Next, it's placed on a mandrel or idler rol that increases the steel ring's diameters and reduces thethickness of its walls. You can find them in machinery and equipment, vehicles, pipes and valves, and other hardware. Almost all vehicles and otherheavy machinery make use of them because they are durable and easy to replace and look for.

Alloy 600 (UNS N06600) is a nickel-chromium alloy designed for use fromcryogenic to

elevated temperatures in the range of 2000F(1093 °C) qood oxidation

resistance at higher temperatures, with good resistance in

carburizing andchloride containing environments. The high nickel

contentof the aloy enables it to retain considerable resistance

under reducing conditions and makes it resistant to corrosion by a

number of organic and inorganic compounds.The nickel content gives

it excellent

resistance to chloride-ion stress-corrosion cracking andalso

provides excellent resistance to alkaline solutions. Its chromium

content gives the alloy resistance to sulfurcompounds and various

oxidizing environments. The chromium content of the alloy makes it

superior to commercially pure nicke under oxidizing

conditions.rstrong oxidizing solutions, like hot concentrated

nitricacid,600 has poor resistance. Alloy 600 is

relativelyunattacked by the majority of neutral and alkaline

saltsolutions and is used in some caustic environments.

Applications

Thermocouple sheaths / Ethylene dichloride (EDC) cracking tubes /

Conversion of uranium dioxide to tetrafluoride in contact with

hydrofluoric acid / Production of caustic alkalis particularly in

the presence of sulfur compounds / Reactor vessels and heat

exchanger tubing used in the production of vinyl chloride / Process

equipment used in the production of chlorinated and fluorinated

hydrocarbons / Furnace retort seals, fans, and fixtures/Roller

hearths and radiant tubes, especially in carbonnitriding processes

/ Heat treating muffles and retorts / Vacuum furnace

fixtures.Chlorination equipment to 1000°F Titanium dioxide plants,

Machining:

Nickel based alloys can be difficult tomachinine.However, it should

be emphasized that thesealloys can be machined using conventional

productionmethods at satisfactory rates. These alloys harden

rapidlygenerate high heat during cutting, weld to the cuttingtool

surface and offer high resistance to metal removabecause of their

high shear strengths. The following arekey points which should be

considered during machining operations: capacity/tools/positive

cut/lubrication.

Chemical Composition:

| Element | Ni+Co | Cr | Fe | C | Mn | S | Si | Cu |

| Minimum(%) | 72 | 14 | 6 | - | - | - | - | - |

| Max(%) | - | 17 | 10 | 0.15 | 1 | 0.015 | 0.5 | 0.5 |

Mean Coefficient of Thermal Expansion & Mechanical Properties:

| Mean Coefficient of Thermal Expansion | ||||

| Temperature Range | ||||

| °F | °C | in/in°F | cm/cm°C | |

| 68 | 20 | 5.8 x 10-6 | 10.4 x 10-6 | |

| Mechanical Properties | ||||

| Typical Values at 68°F (20°C) | ||||

| Yield Strength 0.2% Offset | Ultimate Tensile Strength (min.) | Elongation in 2” | ||

| psi | Mpa | psi | Mpa | % |

| 35000 | 240 | 80000 | 550 | 30 |

Gas Carbonization Tests (100 h) in Hydrogen/2% Methane:

| Gas Carbonization Tests (100 h) in Hydrogen/2% Methane | ||

| Alloy | Weight Gain, mg/cm2 | |

| 1700°F (925°C) | 2000°F (1095°C) | |

| 600 | 2.66 | 12.3 |

| 601 | 2.72 | 16.18 |

| 800HT | 4.94 | 21.58 |

| 330 | 6.42 | 24.00 |

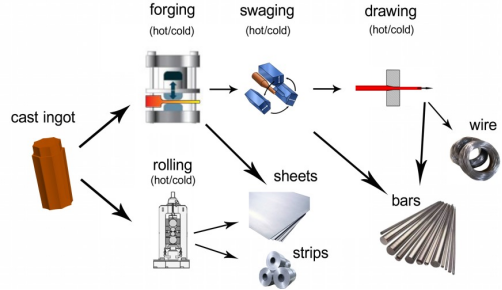

Processing Flow Chart:

|