| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickle Alloy Flat Welding Flange Incoloy 800 Power Station Boiler Pressure Vessel

Nickle Alloy Flange, also known as a flange rim or flange, is a part that connects pipes to each other at the ends, and it is also used on equipment inlets and outlets for connecting two pieces of equipment, such as a reducer flange. A flange connection or flange joint refers to a detachable connection consisting of a flange, gasket, and bolt, which together form a combined sealing structure.

Classification Method:

INCONEL ALLOY 800 (UNS N08800/W. Nr. 1.4876) is a widely used material for construction of equipment requiring corrosion resistance, heat resistance, strength, and stability for service up to 1500°F (816°C). Alloy 800 offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking. At elevated temperatures it offers resistance to oxidation, carburization, and sulfidation along with rupture and creep strength. For applications requiring greater resistance to stress rupture and creep, especially at temperatures above 1500°F (816°C), INCOLOY alloys 800H and 800HT are used. The chromium in the alloy imparts both aqueous and heat resistance. Iron provides resistance to internal oxidation. The nickel content maintains a ductile, austenitic structure. Thus, alloy 800 is readily formed,

Typical Applications:

INCOLOY alloy 800 is used in a variety of applications involving exposure to corrosive environments and high temperatures. It is used for heat-treating equipment such as baskets, trays, and fixtures. In chemical and petrochemical processing, the alloy is used for heat exchangers and other piping systems in nitric acid media especially whereresistance to chloride stress-corrosion cracking is required. In nuclear power plants, it is used for steam-generator

Mechanical Properties:

INCOLOY alloy 800 has high mechanical strength over a broad temperature range. In general, alloy 800 is used for its

Chemical Composition:

| Element | Ni | Cr | Fe | C | Mn | S | Si | Co | Al | Ti |

| Minimum(%) | 30 | 19 | - | 0.1 | 1.5 | 0.015 | 1.0 | 0.75 | 0.15 | 0.15 |

| Max(%) | 35 | 23 | 39.5 | - | - | - | - | - | 0.6 | 0.6 |

Designantion and standards:

| National Standards | Material designation | Forgings | Rod and bar | Plate and sheet | Strip | Wire | Seamless tube |

ASTM ASME SAE NACE | Incoloy 800 UNS N08800 | ASTM B 564 ASME SB 564 | ASTM B 408 ASTM SB 408 | ASTM A 240/A 480 & ASME SA 240/SA 480 | ASTM B 409/B 906 & ASME SB 409/SB 906 | ISO 9724 | ASTM B 163 & ASME SB 163 |

| DIN | 1.4876 |

Thermal Properties:

| Temperature | Electrical Resistivity | Coefficient of Expansion | Thermal Conductivity |

| °F | ohm•circ mil/ft | 10-6 in/in/°F | Btu•in/ft2•h•°F |

| 70 | 595 | - | 80 |

| 100 | 600 | - | 83 |

| 200 | 620 | 7.9 | 89 |

| 400 | 657 | 8.8 | 103 |

| 600 | 682 | 9.0 | 115 |

| 800 | 704 | 9.2 | 127 |

| 1000 | 722 | 9.4 | 139 |

| 1200 | 746 | 9.6 | 152 |

| 1400 | 758 | 9.9 | 166 |

| 1600 | 770 | 10.2 | 181 |

| 1800 | 776 | - | 214 |

| 2000 | 788 | - | - |

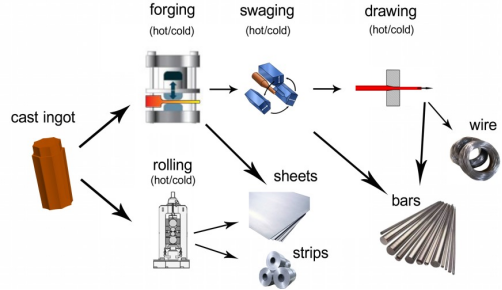

Processing Flow Chart:

|