Nickle Alloy Flat Welding Flange Incoloy 800H Oil Chemical Industry

Shipbuilding

Nickle Alloy Flange, also known as a flange rim or flange, is a part that connects

pipes to each other at the ends, and it is also used on equipment

inlets and outlets for connecting two pieces of equipment, such as

a reducer flange. A flange connection or flange joint refers to a

detachable connection consisting of a flange, gasket, and bolt,

which together form a combined sealing structure.

Connection Method: A flange connection involves securing two pipes, fittings, or

equipment to separate flange plates, and then joining these flange

plates together with a gasket in between and bolting them tightly

to complete the connection. Some fittings and equipment come with

integrated flange plates, and these are also considered flange

connections. Flange connections are a crucial method of pipe

installation, offering ease of use and the ability to withstand

high pressure. They are extensively used in industrial piping

systems. In residential settings, where pipes are of smaller

diameter and operate at low pressure, flange connections are less

visible. However, in locations like boiler rooms or production

facilities, flange connections are prevalent in the piping and

equipment.

Types of Flange Connections:

- plate flange

- necked plate flange

- necked welding flange

- socket welding flange

- threaded flange

- flange cover

- necked welding ring loose flange

- plate welding ring loose flange

- ring groove flange and flange cover

- large diameter flat flange

- large diameter high neck flange

- octagonal blind plate

- welding ring loose flange

The Differences Between Incoloy Alloys 800H / 800HT and Incoloy

800:

- It have significantly higher creep and rupture strength than INCOLOY alloy 800. The three alloys have nearly identical chemical composition limits. However, chemical composition limits vary with carbon, aluminum and titanium. The carbon content of INCOLOY alloy 800 (UNS N08800) is 0.10% max with no limit on the lower end. The carbon content for INCOLOY alloy 800H (UNS N08810) is 0.05 to 0.10%, which is the upper end of the 0.10% maximum specified for INCOLOY alloy 800. The chemical limits for INCOLOY alloy 800HT (UNS N08811) are even more restrictive yet still within the limits specified for INCOLOY alloy 800H. The carbon content for INCOLOY alloy 800HT is further restricted to 0.06 – 0.10%. Additionally, the Al plus Ti content of INCOLOY alloy 800HT is restricted to 0.85 – 1.20%. Note that the chemical composition for INCOLOY alloy 800HT will always be within the limits of INCOLOY alloy 800H. Note also that the limits for INCOLOY alloy 800H may or may not be within the limits of INCOLOY alloy 800HT.

- In addition to the controlled carbon content, INCOLOY alloys 800H and 800HT receive a high temperature annealing treatment that produces an average grain size of ASTM 5 or coarser. The annealing treatment and restricted chemical composition are responsible for these alloys having greater creep and rupture strength.

- For specific applications, chemical and /or grain size limits may differ from the general requirements. For example, some customers require the Al and Ti, for INCOLOY alloy 800H, be limited to 0.4 – 0.7% for intermediate service temperatures [1000° to 1400°F (540° to 760°C)]. These special requirements are as agreed for specific orders. The mechanical properties of INCOLOY alloys 800H and 800HT, combined with their resistance to high temperature corrosion, make these alloys exceptionally useful for many applications involving long-term exposure to elevated temperatures and corrosive atmospheres. In the hydrocarbon processing industry, these alloys are used in steam/hydrocarbon reforming for catalyst tubing, convection tubing, pigtails, outlet manifolds, and quenching-system piping; in ethylene production for both convection and cracking tubes, and pigtails; in oxy-alcohol production for tubing in hydrogenation heaters; in hydrodealkylation units for heater tubing; and in theproduction of vinyl chloride monomer for cracking tubes, return bends and inlet and outlet flanges.

- Industrial heating is another area of wide usage for both INCOLOY alloys 800H and 800HT. In various types ofheat-treating furnaces, these alloys are used for radiant tubes, muffles, retorts, and assorted furnace fixtures. Alloys 800H and 800HT are also used in power generation for steam superheating tubing and high temperature heat exchangers in gas-cooled nuclear reactors

Microstructure and Metallurgy:

- INCOLOY alloys 800H and 800HT are austenitic, solid solution alloys. Titanium nitrides, titanium carbides, and chromium carbides normally appear in the alloys’ microstructure. The nitrides are stable at all temperatures below the melting point and are therefore unaffected by heat treatment.

- Chromium carbides precipitate in the alloys at temperatures between 1000 and 2000°F. Consequently, alloys 800H and 800HT are similar to other austenitic alloys in that they can be rendered susceptible to intergranular corrosion (sensitized) in certain aggressive environments by exposure to temperatures of 1000 to 1400°F (540-760°C).

- INCOLOY alloy 800H and 800HT products are produced so as to optimize their high temperature properties.

- The carbon content in alloys 800H and 800HT results in high temperature strength and resistance to creep andrupture. Alloy 800H and 800HT products are solution annealed as a final stage of production so that the carbon is in the condition to make its optimum contribution to high temperature properties. The solution anneal also results in a large grain size which further contributes to strength and resistance to creep and rupture at high temperatures.

Mechanical Properties:

The major differences between alloys 800, 800H and 800HT are mechanical properties. The differences stem from the restricted compositions of alloys 800H and 800HT and the high-temperature anneals used for these alloys. In general, alloy 800 has higher mechanical properties at room temperature and during short-time exposure to elevated temperatures, whereas alloys 800H and 800HT have superior creep and rupture strength during extended high temperature exposure.

Chemical Composition:

| Element | Ni | Cr | Fe | C | Mn | S | Si | Co | Al | Ti |

| Minimum(%) | 30 | 19 | - | 0.1 | 1.5 | 0.015 | 1.0 | 0.75 | 0.15 | 0.15 |

| Max(%) | 35 | 23 | 39.5 | - | - | - | - | - | 0.6 | 0.6 |

Designantion and standards:

National

Standards | Material

designation | Forgings | Rod and

bar | Plate and

sheet | Strip | Wire | Seamless

tube |

ASTM ASME SAE NACE | Incoloy 800 UNS N08800

| ASTM B 564 | ASTM B 408 | ASTM A 240/A 480 & ASME SA 240/SA 480 | ASTM B 409/B 906 & ASME SB 409/SB 906 | ISO 9724 | ASTM B 163 & ASME SB 163 |

| DIN | 1.4876 | | | | | | |

Thermal Properties:

| Temperature | Electrical

Resistivity | Coefficient of

Expansion | Thermal Conductivity |

| °F | ohm•circ mil/ft | 10-6 in/in/°F | Btu•in/ft2•h•°F |

| 70 | 595 | - | 80 |

| 100 | 600 | - | 83 |

| 200 | 620 | 7.9 | 89 |

| 400 | 657 | 8.8 | 103 |

| 600 | 682 | 9.0 | 115 |

| 800 | 704 | 9.2 | 127 |

| 1000 | 722 | 9.4 | 139 |

| 1200 | 746 | 9.6 | 152 |

| 1400 | 758 | 9.9 | 166 |

| 1600 | 770 | 10.2 | 181 |

| 1800 | 776 | - | 214 |

| 2000 | 788 | - | - |

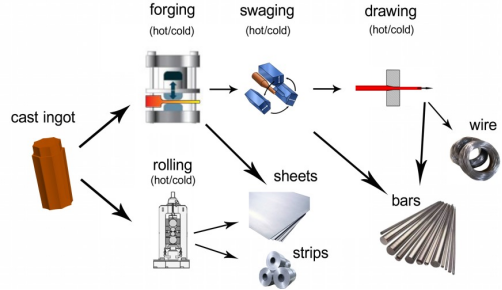

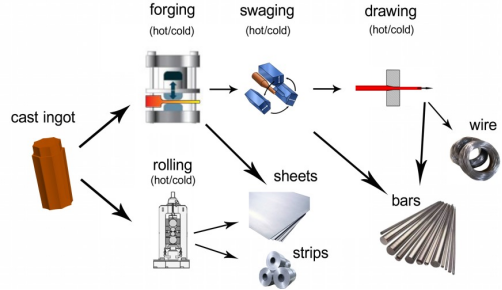

Processing Flow Chart: