| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickle Alloy Flat Welding Flange Hastelloy C4 Catalytic Support System

Nickle Alloy Flange, also known as a flange rim or flange, is a part that connects pipes to each other at the ends, and it is also used on equipment inlets and outlets for connecting two pieces of equipment, such as a reducer flange. A flange connection or flange joint refers to a detachable connection consisting of a flange, gasket, and bolt, which together form a combined sealing structure.

Welding Process:

Hastelloy C4:

This Nickel-Chromium-Molybdenum alloy tolerates high temperatures

and gives a designfreedom in areas where weld geometry makes

excessive heat buid-up unavoidable. Resistance to general and

localised corrosion and stress corrosion cracking is generaly

similar to Hasteloy C-276.With its high contents of Chromium and

Molybdenum Hastelloy C-4 is able to withstand both

oxidizing and non-oxidizing acids, and is resistant to pitting and

crevice attacks in thepresence of chlorides and other halides. Like

other nickel alloys, Hastelloy C-4 is ductile, easy to form and

weld. Hastelloy C-4 is also known as Nicrofer 6616.

Key Features

Hastelloy C-4 offers the following key features: Excelent

resistance to stress-corrosioncracking and to oxidizing atmospheres

at hightemperature. xceptiona resistance to a wide variety of

chemical process environments including, hotcontaminated minera

acids,so vents,chorineformic and acetic acids,and salt waters.

Designations

W.NR 2.4610

UNS NO6455

AWS 052

Specifications

ASTM B574

ASTM B619

Chemical Composition:

| Element | Cr | Mo | Fe | C | Si | Co | Mn | P | S | Ti |

| Minimum(%) | 14 | 14 | - | - | - | - | - | - | - | - |

| Max(%) | 18 | 17 | 3 | 0.015 | 0.08 | 2 | 1 | 0.04 | 0.03 | 0.7 |

Designantion and standards:

| National Standards | Material Identification | Bar | Sheet, Plate or Strip | Pipe - Seamless | Pipe - Welded | Tube - Seamless | Tube - Welded |

ASTM ASME SAE NACE | UNS NO6455 | ASTM B473, ASME SB473 | ASTM B463, ASTM B751, ASME SB463, ASME SB751 | ASTM B729, ASME SB729 | ASTM B464, ASTM B474, ASME SB464, ASME SB474 | ASTM B729, ASME SB729 | ASTM B468, ASME SB468 |

The typical mechanical properties of HastelloyC-4:

| Annealed | ||

| Approx. tensile strength | <1100 N/mm2 | <159 ksi |

| Approx. operating temperature depending on load**and environment | -200 to +400°C | -330 to+750°F |

| Spring Temper | ||

| Approx. tensile strength | 1300- 1700 N/mm2 | 189 -247 ksi |

| Approx. operating temperature depending onload**and environment | -200 to+400 “C | -330 to+750 ℉ |

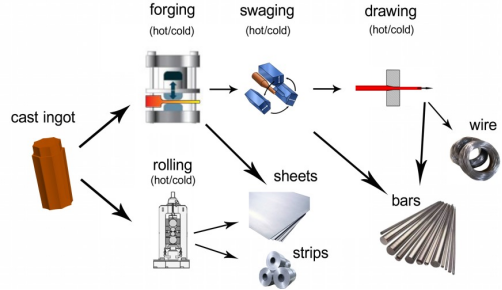

Processing Flow Chart:

|