| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickle Alloy Flat Welding Flange Incoloy 28 Nr. 1.4563 Petroleum Equipment Reactor

Nickle Alloy Flange, also known as a flange rim or flange, is a part that connects pipes to each other at the ends, and it is also used on equipment inlets and outlets for connecting two pieces of equipment, such as a reducer flange. A flange connection or flange joint refers to a detachable connection consisting of a flange, gasket, and bolt, which together form a combined sealing structure.

Welding Process:

Hastelloy C22, is a nickel-chromium-molybdenum alloy with enhanced resistance topitting, crevice corrosion, and stress corrosion cracking.This alloy is resistant to the formation of grain boundaryprecipitates, specifically in the weld-heat affected zone.This attribute makes alloy C-22 suitable for use in the as.welded condition.C-22 has outstanding resistance to both reducing and oxidizing media. Due to these corrosion resistant properties, alloy 22 can be used wherechallenging conditions are likely to occur. The alloy hasoeen proven to possess excelent weldabiity and highcorrosion resistance as consumable filler wires andelectrodes. Alloy C-22 also has proven results as a fillel wire in many applications. C-22 can easily be cold-worked because of its ductility.Cold-forming is the preferred method of forming. Coldworking requires more eneray during production because the alloy is stiffer than austenitic stainless steels. For comparison, a 0.28" thick sheet in the heat-treated at2050°F,rapid quenched condition, has an average olsencup depth of 0.49".

Typical inventory

Round Bar, Loose Coil, Sheet, Plate, Tubing, Fittings

Applications

C-22 is used in severely corrosive media with high chlorideand

temperature applications such as buffer solutions,active

pharmaceutical ingredients (APl), fabric softenerscleaning

supplies, and fish, soy and chili sauce.

General Data

Alloy C-22 is a great alternative when super austeniticstainless steels (AL-6XN®, 904L, and 254 SMO®) andduplex stainless steels (2205 and 2507)will not withstanoextremely aggressive media. This is because it is a nickel-chromium-molvbdenum-tungsten a oy with better overaresistance to uniform and ocalized corrosion than anyother Ni-Cr-Mo alloys such as Hastelloy C-276,C-4, ancalloy 625.

Mechanical Properties

The typical properties listed can usually be provided inrounds, sheet, strip, plate,& custom forgings. We havethe equipment to produce small quantities in special sizesto meet our customers' specific needs

Chemical Composition:

| Element | Ni | Cr | Mo | Fe | Co | W | Mn | Si | C | V |

| Minimum(%) | 56 | 22 | 13 | 3 | 2.5 | 3 | 0.5 | 0.08 | 0.01 | 0.35 |

| Max(%) | Bal. | - | - | - | - | - | - | - | - | - |

Designantion and standards:

| National Standards | Material Identification | Bar | Sheet, Plate or Strip | Pipe - Seamless | Pipe - Welded | Tube - Seamless | Tube - Welded |

ASTM ASME SAE NACE | UNS NO6022 | ASTM B473, ASME SB473 | ASTM B463, ASTM B751, ASME SB463, ASME SB751 | ASTM B729, ASME SB729 | ASTM B464, ASTM B474, ASME SB464, ASME SB474 | ASTM B729, ASME SB729 | ASTM B468, ASME SB468 |

Room Temperature Tensile Test Results of Cold Worked INCOLOY alloy 028:

| Form | Tensile Strength (0.2% Offset) | Yield Strength | Elongation (%) | ||

| ksi | MPa | ksi | MPa | ||

| Sheet 0.028-.0125' | 116 | 800 | 59 | 407 | 57 |

| Plate 0.25- 0.75" | 114 | 786 | 54 | 372 | 62 |

| Bar 0.5-2.0" | 111 | 765 | 52 | 359 | 70 |

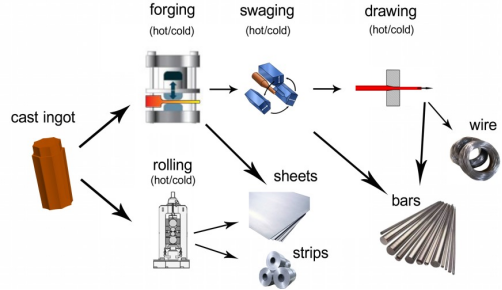

Processing Flow Chart:

|