| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickle Alloy Flanges Inconel 600 Marine structures desalination heat exchange

Nickle Alloy Flange, also known as a flange rim or flange, is a part that connects pipes to each other at the ends, and it is also used on equipment inlets and outlets for connecting two pieces of equipment, such as a reducer flange. A flange connection or flange joint refers to a detachable connection consisting of a flange, gasket, and bolt, which together form a combined sealing structure.

Categories & Application:

INCONEL ALLOY X-750 (UNS N07750/W. Nr. 2.4669) is a precipitation-hardenable

nickel-chromium alloy used for its corrosion and oxidation

resistance and high strength at temperatures to 1300°F. Although

much of the effect of precipitation hardening is lost with

increasing temperature over 1300°F, heat-treated material has

useful strength up to 1800°F. Alloy X-750

also has excellent properties down to cryogenic termperatures.

Typical Applications:

The economics of INCONEL alloy X-750 coupled with its availability in all standard mill forms has resulted in applications in a wide variety of industrial fields. In gas turbines, it is used for rotor blades and wheels, bolts, and other structural members. INCONEL alloy X-750 is used extensively in rocket-engine thrust chambers. Airframe applications include thrust reversers and hot-air ducting systems. Large pressure vessels are formed from INCONEL alloy X-750. Other applications are heat-treating fixtures, forming tools, extrusion dies, and test machine grips. For springs and fasteners, INCONEL alloy X-750 is used from sub-zero to 1200°F.

Heat Treatment:

Depending on the application and the properties desired, various

heat treatments are employed. For service above 1100°F,

particularly where loads are to be sustained for long times,

optimum properties are achieved by solution treating (2100°F) plus

stabilization treating (1550°F) plus precipitation treating

(1300°F). For service below 1100°F, the alloy may be strengthened

by precipitation treating after hot or cold working or by

precipitation treating after equalizing or solution treating. A

furnace-cooling treatment is also used to develop optimum

properties for some applications. The various heat treatments and

the properties

developed are described under the section on Mechanical Properties.

Chemical Composition:

| Element | Cr | Ni | Fe | Nb | Co | Cu | Al | Ti | C | Mn | Si | P | S |

| Minimum(%) | 14 | 70 | 5 | 0.7 | - | - | 0.4 | 2.25 | - | - | - | - | - |

| Max(%) | 17 | - | 9 | 1.2 | 1 | 0.5 | 1 | 2.75 | 0.08 | 1 | 0.5 | 0.015 | 0.01 |

Designantion and standards:

| National Standards | Material designation | Chemical composition | Forgings | Rod and bar | Plate and sheet | Strip | Wire | Seamless tube |

ASTM ASME SAE NACE | UNS NO7750 | B637 SB637 MR 0175 | B637 AMS5668 AMS5671 AMS5747 | B637 AMS5668 AMS5669 AMS5670 AMS5671 AMS5747 | AMS5542 AMS5598 | AMS5542 AMS5598 | AMS5698 AMS5699 | AMS5582 |

| DIN | 2.4669 NiCr15FeTiAl | DIN 10269 | ||||||

| GB/T | GH4145, GH145 | GB/T 14992 DLT 439 | GB/T 14996 |

Thermal Properties:

| Temperature | Mean Linear Expansion, in./in./°F x 10-6 from 70° F to Temperature Shown | Diffusivity, sq ft/hr | Electrical Resistivity | Thermal Conductivity | Specific Heat |

| °F | ohm•circ•mil/ft | Btu•in/ft2•h•°F | Btu/lb•°F | ||

| -250 | 6.0 | 0.150 | - | 67 | 0.073 |

| -200 | 6.6 | 0.143 | - | 70 | 0.080 |

| -100 | 6.7 | 0.135 | - | 74 | 0.090 |

| 70 | - | 0.132 | 731 | 83 | 0.103 |

| 200 | 7.0 | 0.133 | 739 | 89 | 0.109 |

| 400 | 7.2 | 0.140 | 746 | 98 | 0.116 |

| 600 | 7.5 | 0.148 | 761 | 109 | 0.120 |

| 800 | 7.8 | 0.158 | 771 | 120 | 0.125 |

| 1000 | 8.1 | 0.169 | 783 | 131 | 0.130 |

| 1200 | 8.4 | 0.173 | 786 | 143 | 0.137 |

| 1400 | 8.8 | 0.172 | 775 | 154 | 0.151 |

| 1600 | 9.3 | 0.164 | 761 | 164 | 0.171 |

| 1800 | 9.8 | - | - | - | - |

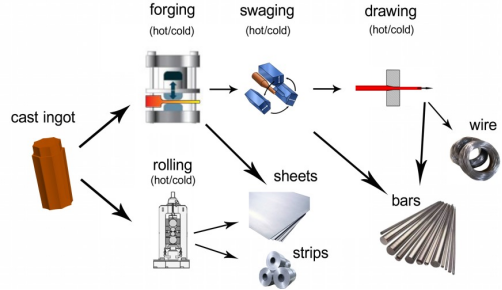

Processing Flow Chart:

|