| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickel Alloy Flat Welding Flange Hastelloy B2 Calcining Furnace Heat Treatment

Nickel Alloy Flange, also known as a flange rim or flange, is a part that connects pipes to each other at the ends, and it is also used on equipment inlets and outlets for connecting two pieces of equipment, such as a reducer flange. A flange connection or flange joint refers to a detachable connection consisting of a flange, gasket, and bolt, which together form a combined sealing structure.

Welding Process:

Hastelloy B3:

This Nickel-Molybdenum alloy gives excellent resistance to hydrochloric acid at all concentrations and temperatures from ambient to high. It also withstands sulphuric, acetic, formic and phosphoric acids and other non-oxidizing media. B-3 also has excellent resistance to pitting corrosion and to stress-corrosion cracking. Hastelloy B-3 is not recommended in the presence of ferric or cupric salts. Like other nickel alloys, Hastelloy B-3 is ductile and can be formed and welded. It resists stress corrosion cracking in chloride-bearing solutions, and is able to withstand fluoride-bearing media and concentrated sulfuric acid, both of which result in damage to zirconium alloys.

Hastelloy B-3 offers the following key features:

W.Nr 2.4600

UNS N10675

AWS 051

ASTM B335

ASTM B619

FORMS

Coil -Sheet, Strip, Foil Wire -Profile, Round,Flat, Square, Flange

Chemical Composition:

| Element | Ni | Cr | Mo | Fe | W | C | Si | Co | Mn | V | P | S | Ti |

| Minimum(%) | 65 | 1 | 27 | 1 | - | - | - | - | - | - | - | - | - |

| Max(%) | - | 3 | 32 | 3 | 3 | 0.01 | 0.1 | 3 | 3 | 0.2 | 0.03 | 0.01 | 0.2 |

Designation and standards:

| National Standards | DIN | VdTÜV Datasheet | Bar | Sheet, Plate | Pipe - Seamless | Pipe - Welded | Strip | Wire | ||

ASTM ASME | 17744 17750 17751 17752 17753 NiMo29Cr 2.4600 | 517 | ASTM B333, ASME SB333 | ASTM B335, ASME SB335, | ASTM B564, | ASTM B619, ASME SB649, | ASTM B622, ASME SB622 | ASTM B626, ASME SB626 | ||

| Delivery Forms | rolled or forged, solution annealed | hot rolled, solution annealed, pickled or de-scaled | longitudinally, seamless, | bright/solution annealed, welded | cold rolled, bright/solution annealed | rolled or drawn | ||||

The typical mechanical properties of Hastelloy B3:

| Annealed | ||

| Approx. tensile strength | <1200 N/mm2 | <174 ksi |

| Approx. operating temperature depending on load**and environment | -200 to +400°C | -330 to+750°F |

| Spring Temper | ||

| Approx. tensile strength | 1600- 2000 N/mm2 | 232 -290 ksi |

| Approx. operating temperature depending onload**and environment | -200 to+400 “C | -330 to+750 ℉ |

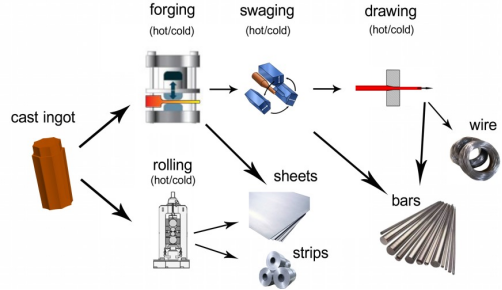

Processing Flow Chart:

|