| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DINGSCO |

| Model Number : | According to customers requirements |

| Certification : | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | Negotiable |

| Delivery Time : | (Sample Order) 7 days |

Nickle Alloy Flat Welding Flange 254 SMO 6MO Super Dupex F44 1.4547 UNS S31254

Nickle Alloy Flange, also known as a flange rim or flange, is a part that connects pipes to each other at the ends, and it is also used on equipment inlets and outlets for connecting two pieces of equipment, such as a reducer flange. A flange connection or flange joint refers to a detachable connection consisting of a flange, gasket, and bolt, which together form a combined sealing structure.

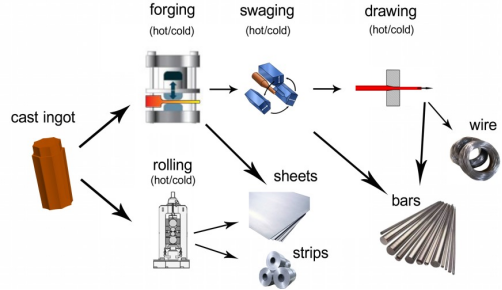

Welding Process:

UNS S31254 / 1.4547 / F44:

Chemical Composition:

| Element | C | Mn | Si | S | P | Cr | Ni | Mo | N | Cu |

| Minimum(%) | - | - | - | - | - | 19.5 | 17.5 | 6 | 0.18 | 0.5 |

| Max(%) | 0.02 | 1 | 0.7 | 0.01 | 0.03 | 20.5 | 18.5 | 7 | 0.25 | 1 |

| ASTM | S31254 / A182 / A276 / A479 / A240 / A312 / A312 |

| ASME | S31254 / SA182 / SA276 / SA479 / SA240 / SA312 / SA312 |

| Machinability | 1. Stainless steel grade 254 SMO™ is quite tough to machine due to the extremely high work hardening rate and lack of sulfur content; 2. however using sharp tools, overpowered machine tools, positive

feeds, good amount of lubrication, and slow speeds tend to provide

good machining results. |

| Welding | 1. Welding of stainless steel grade 254 SMO™ requires filler material without which it results in poor strength properties. 2. Filler metals such as AWS A5.14 ERNiCrMo-3, and alloy 625 are recommended. 3. Electrodes used in the process, have to match with AWS A5.11

ENiCrMo-12. |

| Annealing | Annealing of this material should be performed at 1149-1204°C (2100-2200°F), which should be followed by a water quench. |

| Hot Working | 1. Forging, upsetting and other operations relating to this material can be performed at 982 – 1149°C (1800 – 2100°F). 2. It is recommended that temperatures do not exceed this range as it would result in scaling and reduction in the workability of the material. 3. To re-attain maximum corrosion resistant properties, it is

advisable to perform post-process annealing. |

| Cold Working | 1. Cold working can be carried out using all the traditional methods; 2. however the process would be tough due to its high work hardening rate. 3. The result will provide the material with increased strength and

toughness. |

| Hardening | 1. Stainless steel grade 254 SMO™ does not respond to heat treatment. 2. Hardening is possible only through cold reduction. |

Processing Flow Chart:

|